Mara Tape Manufacturer: Application and Quality Requirements of Gold Finger Tape

Release time:

2022-08-16

Mara tape manufacturer: gold finger tape is based on polyimide film, coated with high temperature resistant silicone adhesive. It has the characteristics of environmental protection, high temperature resistance, corrosion resistance, high adhesion, good shearing, no residual glue tearing, easy punching and die cutting. Resistance to temperature is generally between 120 degrees and 260 degrees.

Marla tape manufacturers: Gold finger tape is based on polyimide film and coated with high temperature resistant silicone adhesive. It has the characteristics of environmental protection, high temperature resistance, corrosion resistance, high adhesion, good shearing, no residual glue tearing, easy punching and die cutting. Resistance to temperature is generally between 120 degrees and 260 degrees.

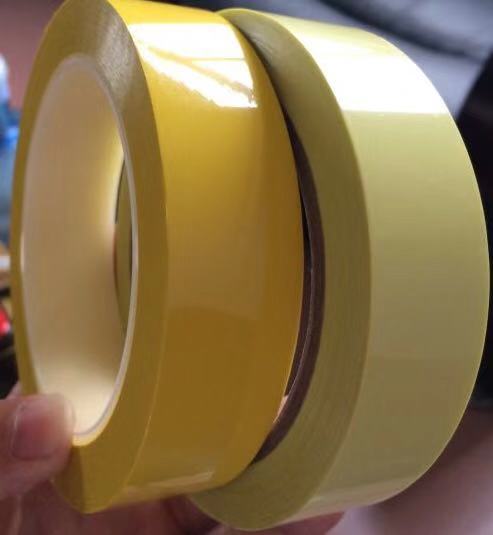

Mara tape manufacturer: gold finger tape is generally brown or golden yellow in color, with widths of 10mm, 15mm, 20mm, 25mm, etc. Length: 33 m/roll. And its coating accuracy can reach ± 2.5um, and there will be no scratches, wire drawing and other phenomena, so it should be widely used in many industries.

Mara Tape Manufacturer: Gold Finger Tape is mainly used in SMT industry for wave wax and reflow soldering gold finger protection, paint, paint leather processing, paint masking and electronic parts manufacturing process, printed circuit board and high temperature processing masking, lithium battery manufacturing industry, surface mount technology, transformer manufacturing and other industries. Gold finger tape is suitable for the manufacture of electronic products such as coils, wire wound insulation, capacitors, etc. Gold finger tape is also commonly used for winding coils, transformer motors, capacitors and wires, lithium battery pole ear fixing, electronic products heating process protection and various high temperature shielding protection.

1. Mara Tape Manufacturer: Application of Gold Finger Tape

1. Electronic protection sticker

Mara tape manufacturer: gold finger tape is especially suitable for SMT temperature protection, electronic switches, PCB boards, gold finger protection electronic transformers and other electronic components that need high temperature and moisture resistance.

2. Electronic circuit board

Usually suitable for wave soldering shielding of electronic circuit boards, protective gold fingers and electrical insulation, as well as motor insulation, lithium battery positive and negative ear fixation;

3. Insulation of electronic products

Mara Tape Manufacturer: Gold Finger Tape can be used for insulation winding of H-class motors and transformer coils, winding and fixing of high temperature resistant coil ends, thermal resistance protection and other adhesive insulation functions under high temperature conditions.

4. Metal materials

As well as some precious metals need to be painted at high temperature, sandblasting is used to shield and protect the product, and the high temperature paint is easy to peel and does not residue after baking;

Quality requirements of 2. gold finger tape

1. The viscosity of the gold finger tape should last for a long time and cannot be dried after a period of time;

2. When the golden finger tape is torn off, it should be able to be torn off as a whole;

3. After the peeling is completed, the golden finger tape cannot have residual glue or photographic phenomenon;

4. After the gold finger tape is bonded for a long time, there is no bubble floating or warping;

5, gold finger tape in outdoor use must have weather resistance;

6, gold finger tape can not have crystal point.

Marla tape manufacturers: Gold finger tape has high and low temperature resistance, acid and alkali resistance, electrical insulation, radiation resistance and other properties, high adhesion, soft clothing, no residual glue tearing. The advantage is that when the gold finger tape is torn off after use, the surface of the protected object will not produce residual glue.

Key words:

Related News

Messages

Contact us

Add: Fortune Building, south of Fuqian Road, Shiwan Town

Tel:+8613421383659(Mr. Long)

Tel:+8618948266511(Miss. Long)

E-mail: sales@gdgydz.cn

E-mail: service@gdgydz.cn

Chinese website:玛拉胶带.网址